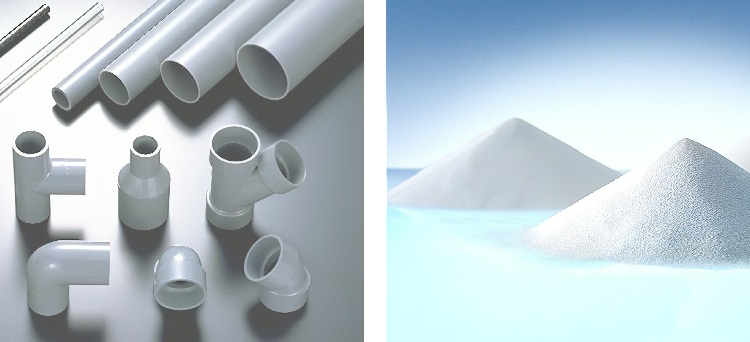

Polyvinyl Chloride(PVC)

PVC; It is the leading raw material for profiles, pipes, cables and many more applications. Additives are needed to process PVC. Stabilizer; It is a collection of chemicals that are required for the processing of PVC and play a critical role in ensuring the development of the final product with the desired properties and strength. Combined with the lubricants and other additives that give strength, they offer special solutions for every demand.

PARAMETERS

In the selection of the stabilizer to be used, many parameters such as process conditions (rheology) and process range, yield, price, sustainability, REACH and other legal issues, and technical characteristics of the final product (sun resistance, brightness, color, stability, etc.) are at the forefront.

EPVC SOLUTIONS

Polkimex has the power to supply from different manufacturers for EPVC solutions needed for special productions.

Polyvinyl Chloride (PVC) is one of the most widely used polymers in the world. Due to its versatile nature, PVC is frequently used in a wide variety of industrial, technical and everyday applications, including its extensive use in building, transportation, packaging, electrical/electronic and healthcare applications.

PVC is a very durable and long-lasting material that can be used in a variety of applications, rigid or flexible, white or black, and a wide range of colors in between.

The first patent for the polymerization process for PVC production was granted to German inventor Friedrich Klatte in 1913, and PVC has been commercially produced since 1933. PVC is currently the most used product after polyethylene, accounting for about 20 of all plastic produced worldwide.

The basic raw materials for PVC production are obtained from salt and oil (petroleum-based). Chlorine obtained by electrolysis of salt water is combined with ethylene (obtained from oil) to obtain vinyl chloride monomer (VCM). VCM molecules are supported with suitable catalysts and polymerized to form the desired PVC resin.

Popular methods used to produce PVC commercially include:

Suspension PVC (S-PVC)

Emulsion PVC (E-PVC)

Properties of PVC Polymer

PVC is a versatile and cost-effective material. Its main features and benefits are:

Electrical Properties: PVC is a good insulating material thanks to its good di-electric strength.

Durability: PVC is resistant to weathering, chemical rot, corrosion, shock and abrasion. For this reason, it is preferred for many long-lasting, outdoor products.

Flame Retardant: Due to the high chlorine content, PVC products are self-extinguishing. Its oxidation index is ≥45.

Cost/Performance Ratio: PVC has good physical and mechanical properties and provides excellent cost-performance advantages. It is long lasting and requires little maintenance.

Mechanical Properties: PVC is wear resistant, light and strong.

Chemical Resistance: PVC is resistant to all inorganic chemicals. It has very good resistance to dilute acids, dilute alkalis and aliphatic hydrocarbons.

Usage areas:

PVC is a versatile material that offers many possible applications, including; Window profiles, drainage pipe, water service pipe, medical devices, blood storage bags, cable and wire insulation, flexible flooring, roofing membranes, stationery, automotive interior and seat covers, fashion and footwear, packaging, cling film, credit cards, vinyl plaques, synthetic leather and other coated fabrics.