Polyoxymethylene (POM)

Polyoxymethylene (POM)

Polyacetal, also commonly known as acetal or polyoxymethylene (POM), is a formaldehyde-based, semi-crystalline engineering thermoplastic containing a functional group of carbon attached to two -OR groups. 100% recyclable. POM is known as polyformaldehyde, polymethylene glycol and polyoxymethylene glycol.

Acetal resins are produced by the polymerization of purified formaldehyde [CH2O]. However, different manufacturing processes are used to produce homopolymer and copolymer versions of POM. Copolymers are more stable than homopolymers in alkaline environments. On the other hand, homopolymers provide better mechanical properties than copolymers.

FEATURES

Polyoxymethylene resins exhibit well-balanced properties ranging from mechanical to physical to flammability performance. Key benefits of POM resins include:

Excellent mechanical properties in a temperature range up to 140°C, down to -40°C.

High tensile strength, hardness and toughness (short term).

Low propensity to creep (compared to nylon) and fatigue (long term). Not susceptible to environmental stress cracking.

High degree of crystallinity and excellent dimensional stability.

Excellent wear resistance.

Low coefficient of friction.

Good resistance to organic solvents and chemicals (except phenols) at room temperature.

Low smoke emission.

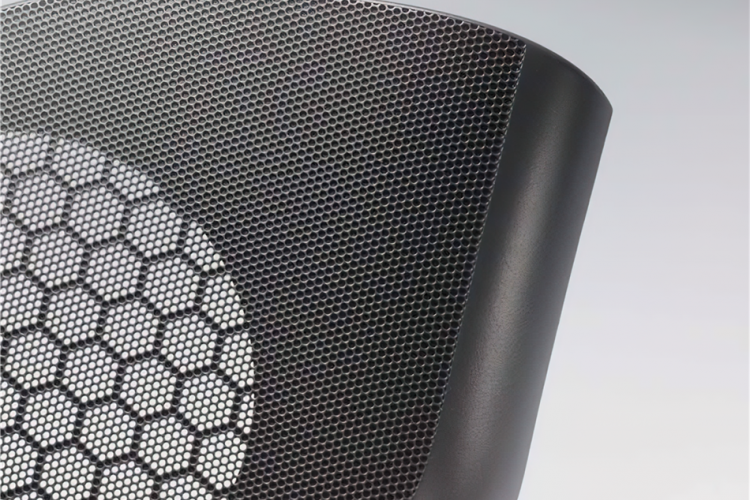

Glossy surfaces.

Low moisture absorption.

usage areas

Acetal Copolymer resin is used in applications that require a combination of strength, low moisture absorption, chemical resistance and dimensional stability. It is also used for high performance engineering components. Acetal Copolymer is widely used in the consumer electronics industry and the automotive industry.

horoscope

rollers

Wear Strips

Small Toothed Wheels

ball bearings

Connectors

Gas Meters

medical technology

Disposable Applications

Aerosol Valves

Lock Systems

Fuel Tank Modules