Polycarbonate (PC)

Transparency, excellent toughness, thermal stability and very good dimensional stability make Polycarbonate (PC) one of the most widely used engineering thermoplastics. Compact discs, riot shields, vandal proof glasses, feeding bottles, electrical components, safety helmets and headlight lenses are typical applications for PC.

Polycarbonate is most commonly formed by the reaction of bis-phenol A (produced by condensation of phenol with acetone under acidic conditions) with carbonyl chloride in an interfacial treatment. PC belongs to the family of polyester plastics.

Polycarbonate remains one of the fastest growing engineering plastics as new applications are defined; global PC demand exceeds 1.5 million tons.

Features

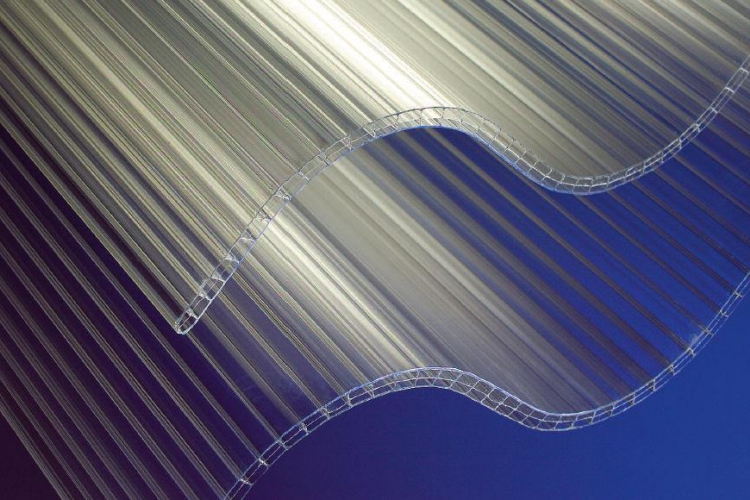

Polycarbonates are strong, rigid, tough, durable, transparent engineering thermoplastics that can hold hardness up to 140°C and toughness down to -20°C or special grades even lower. The material is amorphous (thus showing excellent mechanical properties and high dimensional stability), thermally resistant to 135°C and rated as slow burning. Special flame retardant grades are available that have passed several severe flammability tests.

Restrictions on PC use include limited chemical and scratch resistance and a tendency to yellow with prolonged exposure to UV light. However, these limitations can be easily overcome by adding the correct additives to the compound or by processing with a co-extrusion process.

Scope of application

Polycarbonate blends have become increasingly important commercially in recent years. PC is widely used in blends due to its excellent compatibility with a number of polymers. Typical blends include rubber-modified PC, PC/PBT blends that allow to maintain toughness at lower temperatures and have improved fuel and weather resistance, improving impact properties. Among the most important are those containing ABS (Acrylonitrile Butadiene Styrene). PC/ABS blends exhibit high melt flow, very high toughness at low temperatures and improved stress crack resistance compared to PC.

All Blends are produced using a coupling step to blend the polymers. This coupling technology is crucial to create the optimal morphology and interaction between the two phases. Combined with the right additive information (flame retardant, stabilization, reinforcement) blends are obtained with a range of optimally balanced properties.

PC finds use in a number of markets, particularly in the automotive, glass, electronics, construction equipment, optical media, medical, lighting and device markets.

Examples of typical technology applications include:

Power distribution (covers and enclosures)

connectors

electrical appliances

Mobile phones

Electric chargers

Lighting

battery boxes

automotive lighting

head lamp lenses

boards

inner lining

Exterior parts (bumpers, body panels)

power tools

baby bottles

water dispensers

garden equipment

Furniture

sports equipment

medical applications